Proven Benefits of DESS® Flat Seat Screw

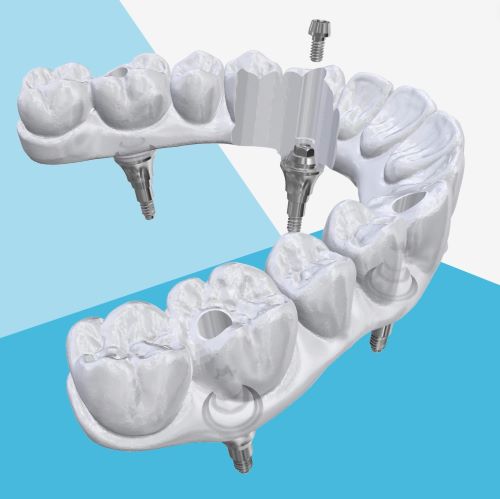

DESS® has recently launched the Flat Seat Screw, a new solution for Full-Arch restorations such as direct to MUA or direct to implant prostheses.

Through testing made by our engineering department we have proven that DESS® Flat Seat Screw is the most effective solution on those cases, since it allows a higher preload force between full arch and MUA as well as permitting divergences in the milling screw holes. It also offers a safe and predictable surface contact area and better control of the screw positioning height & turns when tightened. It offers better absorption of the superstructures milling divergences and self-centering of the screw towards the axis of the MUA. Furthermore, the Torx version allows angulation of the screw channel (ASC).

To better explain the multiple benefits of DESS® Flat Seat Screw on a more technical level, we have developed a list of facts that we hope will be of use when it comes to getting your restorations to the next level.

How to Angulate the Screw Channel on DESS® Torx Flat Seat Screw

- The ASC features need to be milled properly to be able to angulate the screw channel. As in any ASC milling, specific tools and machinery are needed.

- To properly mill any type of ASC, as well as having the right milling tool, the milling needs to be performed from underneath. Milling from the occlusal side will to not getting the correct screw seat surface, which might create problems such as untightening.

- After analysing current screws for MUA bridges on the market, our engineering department concluded that it’s more important to have a correct prosthetic functionality (prosthetic + screw + implant axis + passivity) than being able to mill it by anyone in any case. To achieve such a good result, there is the need of milling with a T- tool.

Milling T-tools considerations:

- When milling no shrinking materials, the T tool needs to be Ø1.4mm, and the shank should be 0.6mm. That depends on the shrinkage factor of the material.

- When milling zirconia, the T tool to be used can have Ø1.6mm and the shank can be a bit bigger than the Ø1.4mm T tool.

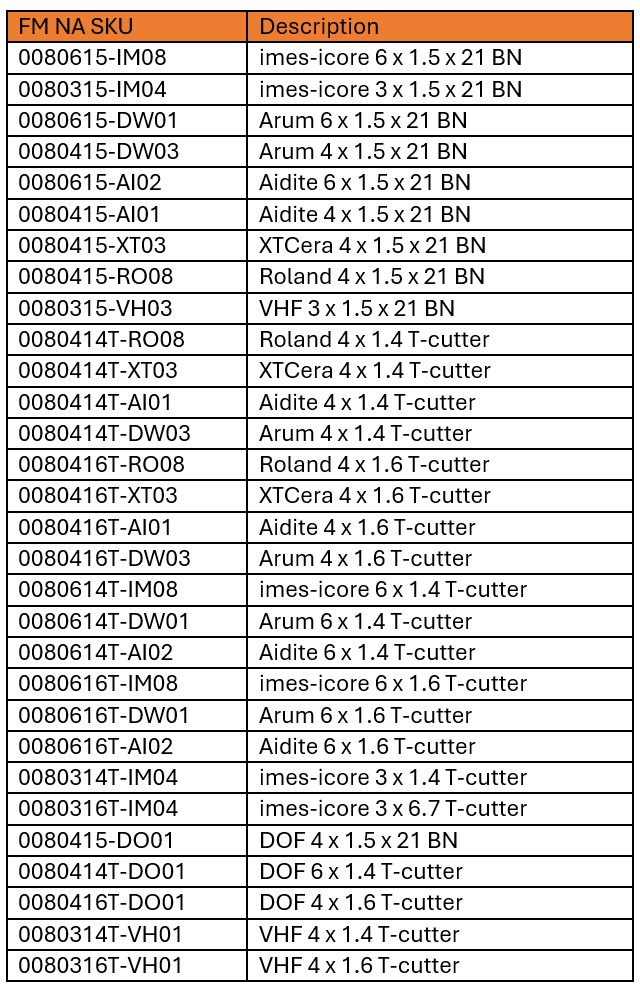

- These specialized tools are available for purchase directly from Follow-me Hyperdent USA, ensuring you have access to the right equipment for precise milling results.

Below is a detailed list of T-tools available through Hyperdent, organized by SKU, description, and machine compatibility

Milling machines or tools capacities:

- Before launching our new Flat Seat Screw, we collaborated with Follow-me Hyperdent USA, a leader in CAM solutions known for its expertise with T-tool strategies, to develop an optimal strategy and tool for milling our designs. They assured us that incorporating this approach would be seamless, as they already have such strategies in place and readily available for those who need them. Additionally, Follow-me Hyperdent USA provides the precise T-tools required for these specific strategies, ensuring that our customers have access to the best tools for their milling projects.

- It is recommended that any entity looking to mill this type of design contact their CAM supplier to implement the necessary strategies, ensuring the accuracy of the milling process. Those who choose not to seek assistance are likely to possess the expertise to proceed independently.

Load/Preload Facts

We have rigorously tested our new screw design against the existing Rosen model, which has demonstrated several disadvantages in comparison. Our tests focused on the load and preload capabilities of both screws. Results indicate that our design supports a significantly higher load capacity, even when the Rosen screw is tightened to 20Ncm and ours is set at just 15Ncm. This highlights the superior performance and efficiency of our product.

Conclusive facts about DESS® Flat Seat Screw

In conclusion, the DESS® Flat Seat Screw represents a significant advancement in Full-Arch restoration technology. Through rigorous engineering tests and collaboration with industry leaders like Follow-me Hyperdent USA, DESS® has developed a screw that not only enhances the precision and functionality of dental prostheses but also simplifies the milling process with specialized T-tool strategies.

Our comprehensive analysis demonstrates that the Flat Seat Screw offers superior load capacity, improved contact area, and better control over screw positioning, distinguishing it from other options currently available on the market. By ensuring high-quality results and facilitating easier implementation, the DESS® Flat Seat Screw is set to revolutionize the standard for dental restoration, providing unparalleled support and reliability to both clinicians and patients. For those committed to achieving the best in prosthetic function and restoration aesthetics, the DESS® Flat Seat Screw is an indispensable tool.